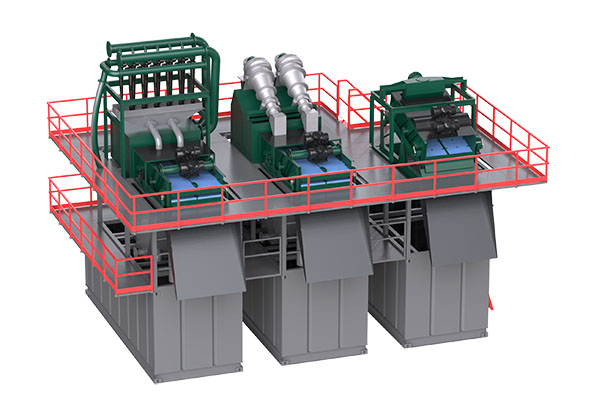

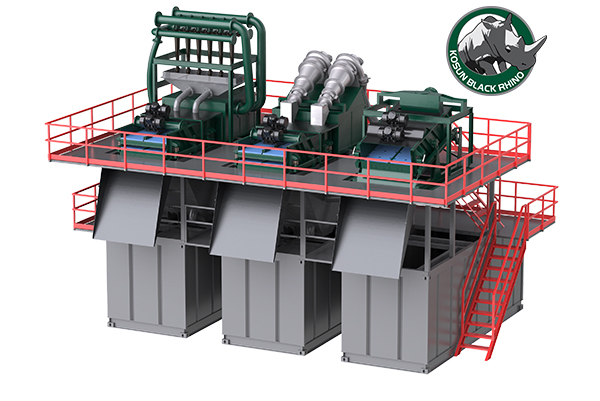

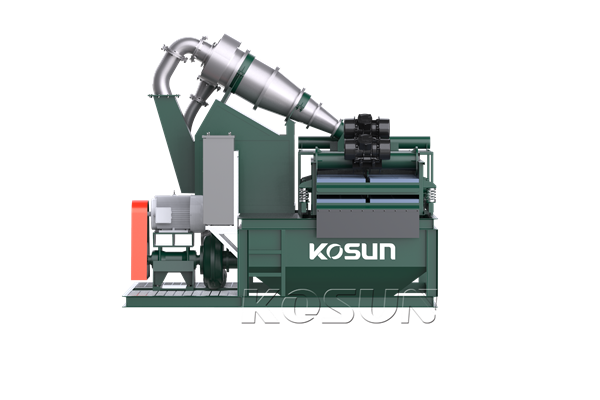

Xi’an KOSUN KD-200 mud treatment system is mainly composed of a shale shaker, desilter, cone tank, slurry distributor, and electrical control equipment.

The KD-200 mud treatment system from Xi’an KOSUN is capable of separating larger solid particles from the slurry, reducing the solid content. The slurry processed by this system can then enter the next-level treatment equipment such as a centrifuge or filter press.

The KD-200 mud treatment system adopts a modular design. It consists of a shale shaker, desilter, cone tank, and slurry distributor. The slurry enters the screening system through the slurry distributor and undergoes step-by-step treatment on the coarse screen mesh of the vibrating screen, desilter, and fine screen mesh of the vibrating screen. This effectively separates the sand, stones, and other excavated materials carried in the slurry, removing larger solid particles from the tailings and reducing the solid content of the slurry. The slurry processed by this system can then enter the next-level treatment equipment such as a centrifuge or filter press.

Xi’an KOSUN specializes in providing solid-liquid separation equipment, widely used in various fields such as oil drilling mud treatment, drilling waste management, oily sludge treatment, construction slurry treatment, shield tunneling slurry separation, subway muck treatment, and sedimentation pond coal slurry treatment.

Please feel free to contact us if you have a project regarding sludge water separation that needs to be handled, we will provide you with a solution. We can provide equipment, or technical support for your project after evaluation.

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

WhatsApp/Wechat:+86 13379250593

Contact person: Monica Li

Online consulting:

http://www.kosun.com

http://www.kosuneco.com