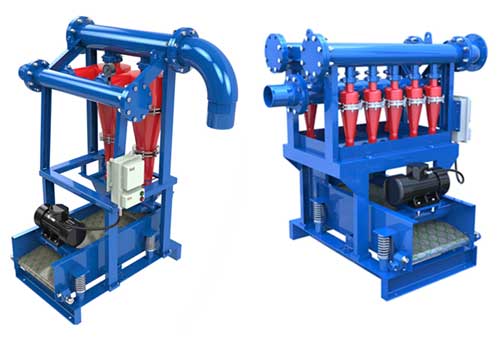

In the field of pipe jacking engineering, the use of mud separation device is essential. These devices are designed to remove solids from the slurry so that the separated water can be used for pipe jacking operations. One of the major manufacturers of this critical equipment is KOSUN Machinery, which recently delivered a mud separation device set to a pipe jacking engineering company.

This slurry separation plant works by using a shale shaker to remove solids. After a series of vibrating screen separation processes, most of the particles will be removed from the slurry, and the separated water can be returned to the pipe jacking operation. The first stage is the vibrating screen, which removes larger particles. The screen used depends on the particle size distribution. The KOSUN engineering team can provide suitable screen opening options.

KOSUN Machinery is known for supplying different types of separation equipment to the world market, including decanters, centrifuges and cuttings dryers. Their expertise in manufacturing state-of-the-art equipment makes them a reliable choice for companies requiring reliable, efficient slurry separation solutions.

The importance of mud separation equipment in pipe jacking projects cannot be overstated. The use of these equipment not only ensures effective removal of solids from the slurry but also contributes to the overall success of the pipe jacking operation. By utilizing slurry separation equipment, companies can reduce downtime, increase productivity, and minimize the environmental impact of their operations.

As environmental regulations become more stringent, the need for efficient slurry separation equipment becomes increasingly important. KOSUN Machinery understands this need and has developed cutting-edge technology to solve the challenges faced by pipe jacking engineering companies. Their commitment to providing high-quality equipment and exceptional service has made them a trusted partner to companies around the world.

In addition to its expertise in separation equipment, KOSUN Machinery provides comprehensive support and maintenance services for its products. This ensures companies can rely on their equipment to perform at its best, reducing the risk of downtime and costly repairs. With KOSUN Machinery as a partner, companies can rest assured knowing that their slurry separation needs are well met.

As the demand for reliable, efficient slurry separation equipment continues to grow, KOSUN Machinery remains at the forefront of innovation. They are dedicated to research and development to create state-of-the-art equipment that meets the ever-changing needs of the industry. With its focus on quality, performance and sustainability, KOSUN Machinery is expected to remain a leader in slurry separation equipment.

In summary, the importance of mud separation devices in pipe jacking projects cannot be overstated. These plants play a vital role in the efficient and environmentally friendly operation of pipe jacking projects. With a reliable partner like KOSUN Machinery, companies can ensure they have access to the best equipment and support for their slurry separation needs. Whether it’s removing solids from mud or ensuring the successful completion of a pipe jacking project, KOSUN Machinery is the first choice of companies around the world.