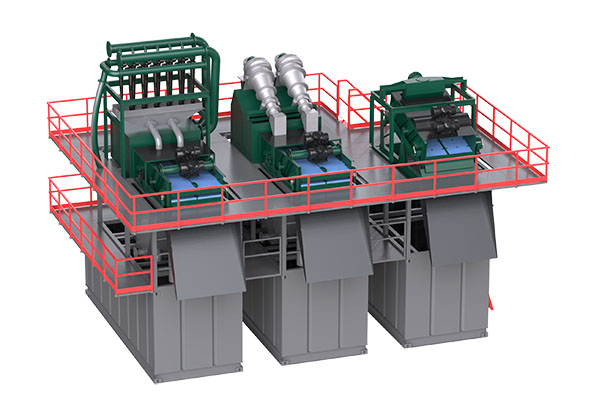

Solids control system equipment selected according to the drilling depth. The choice of equipment for the same well depth in different regions is also different. Generally, we will choose according to the model of the drilling rig, from ZJ20-ZJ90, under normal circumstances, ZJ30 drilling rig only needs 3 levels of solids control equipment, namely: drilling fluid shale shaker, de-sander, and desilter.

Above ZJ30 is a level 5 purification equipment: drilling fluid shale shaker, vacuum degasser, de-sander, desilter, drilling fluid centrifuge. Among them, the mud tank is indispensable as a carrier. The commonly used mud tank specifications are: 95000x2300x2100mm and 125000x2400x2300mm. The number of mud tanks is calculated according to the total volume of the drilling mud, and the appropriate number and size are selected. The amount of circulating mud that needs to be processed is approximately 65% of the total volume of the mud tank. The processing capacity of the solids control equipment at all levels can be selected to meet the circulating mud volume or slightly larger.

The main equipment in the solids control system is the 5-level purification equipment, shale shaker, vacuum deaerator, desander, desilter, centrifuge. The choice of equipment is flexibly selected according to different drilling rigs, and other auxiliary equipment is also indispensable. Desander and desilter must be powered by sand pumps one-to-one. Centrifuges can be supplied by submerged slurry pumps or screw pumps. Where there is a agitator, you must bring a mud gun. The mud gun can flush the dead corners of the tank and start the auxiliary agitator. In addition, the jet mixing device in the solids control system is also indispensable. The jet mixing device can exist as a separate entity, or it can be directly connected to the tail end of the mixing tank and connected by a pipe manifold.

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

WhatsApp/Wechat:+86 18792396268

Contact person: Lily Wang

Online consulting:

http://www.kosun.com

http://www.kosuneco.com