In 2019, KOSUN completed the production and commissioning of a set of KD-250 Excavator-Mounted Integrated Environmental Microtunnelling Sludge Separation System and shipped them to Poland for a sludge separation project in micro-tunnel construction.

This set of equipment has been successfully applied in Poland and has received praise from the customer.

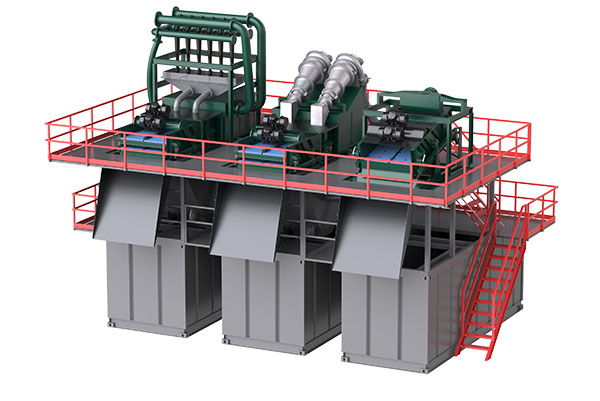

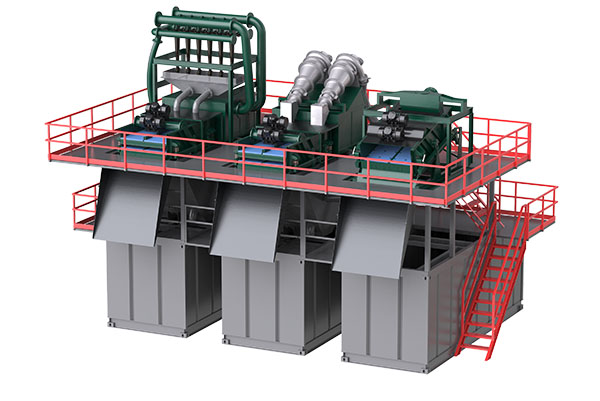

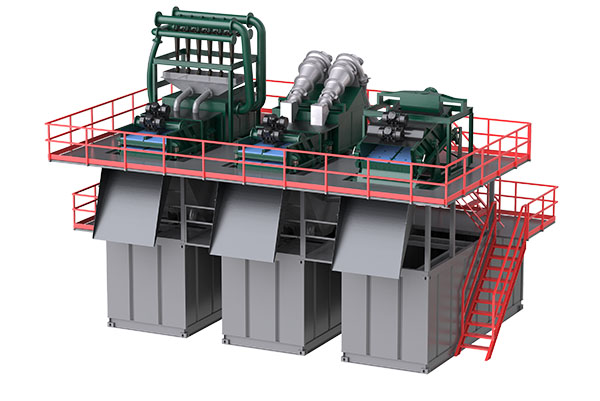

The KOSUN KD-250 Excavator-Mounted Integrated Environmental Microtunnelling Sludge Separation System adopts a modular structural design, consisting of a shale shaker, a decanter centrifuge, a cone tank, and a cloth distributor. The slurry enters the screening system through the cloth distributor. After step-by-step processing by the coarse screen of the shale shaker, the decanter centrifuge, and the fine screen of the shale shaker, it can effectively separate the sand and stones carried in the slurry. It can remove larger solid particles from the tailings, reduce the solid content in the mud, and the slurry processed by the system can enter the next-level processing equipment such as a centrifuge or a filter press.

The shale shaker used in this system is the double-layer linear shale shaker LS-608 series. The main components include the screen box assembly, the shaft seat, the handwheel lifting device, the adjusting beam assembly, and the locking device assembly, etc. KOSUN LS-608 is a linear vibration machine equipped with two vibration motors, featuring the ability to adjust the screen frame angle. During the operation of the shale shaker, the screen frame angle can be adjusted between -1° to +5°. Thanks to the innovative structural design, the KOSUN LS608 shale shaker can efficiently separate solid particles in the slurry. The vibration motors are fixed and positioned on the screen frame with high-strength support beams, and this positioning of the vibration motors allows the exciting force (G-force) to act directly on the screen panel. The vibration isolation device can protect the base frame from the impact of screen frame vibration.

KOSUN has accumulated rich experience in the development of environmental sludge treatment and has numerous on-site application cases at home and abroad. For more information on environmental sludge treatment equipment, please feel free to contact us at any time.

Tag: Microtunnelling Sludge Separation System

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

WhatsApp/Wechat:+86 13379250593

Contact person: Monica Li

Online consulting:

http://www.kosun.com

http://www.kosuneco.com