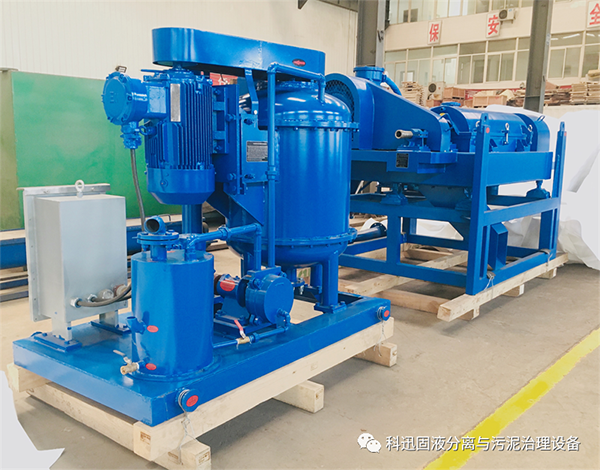

Recently, KOSUN exported a batch of solids control equipment to Russia and sent them to the drilling project site in Russia. So far, KOSUN has sold several batches of solids control equipment to the Pan-Russian region. The pan-Russian market is one of the regions where KOSUN has cooperated for the longest time and has the largest market share. The main equipment supplied this time includes centrifuges, vacuum deaerators, screw pumps and other products.

In recent years, with the in-depth implementation of the “One Belt, One Road” policy, Sino-Russian relations have become more and more consolidated, and the commercial trade between the two sides has also developed rapidly. For this rapidly emerging overseas market, foreign trade people from all walks of life are high-spirited and open up the pan-Russian market through various channels. At the same time, KOSUN is also constantly striving to find better ways for more products to go abroad, insist on innovation, actively Adapt to market changes. Faced with the current unstable situation, our company has overcome all unfavorable factors and continuously and stably provided drilling mud solids control equipment to customers in the Pan-Russian region. The continuous ordering of customers also shows their trust and recognition of our company’s products. KOSUN never forgets its original intention, and strives to serve every customer well and meet all customer needs.

KOSUN is a manufacturer specializing in the production of drilling solids control equipment, mud zero discharge equipment, and oily sludge treatment equipment. We look forward to your inquiry!

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

WhatsApp/Wechat:+86 18792396268

Contact person: Lily Wang

Online consulting:

http://www.kosun.com

http://www.kosuneco.com