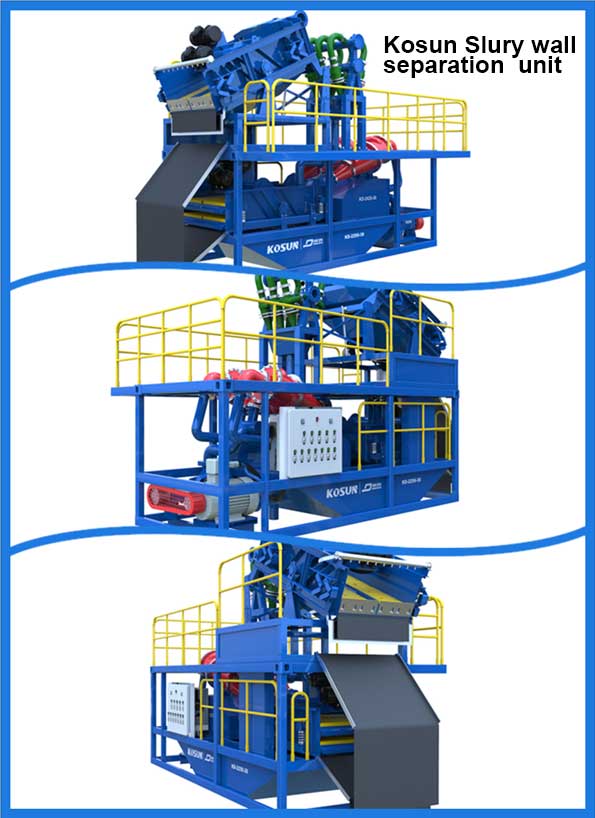

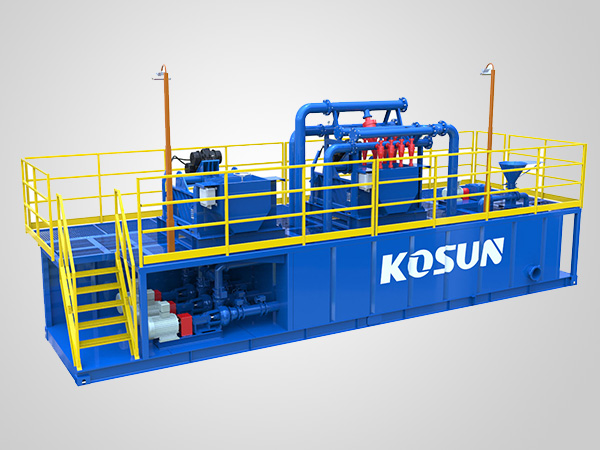

Pipe jacking machines separation units

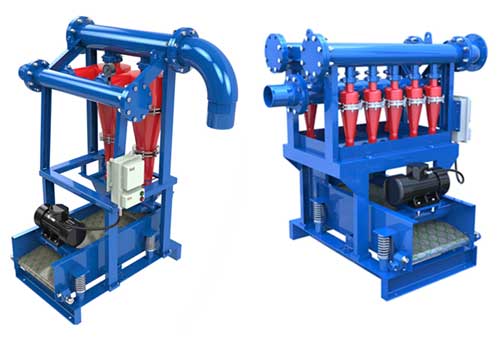

Pipe jacking machines separation units by Kosun treat water before it goes to drains and to the environment. Though lots of efforts are taken to establish more plants, even more are needed. Water is our renewable resource but is slowly being squandered. Pipe jacking machines separation units is one way to recycle waste water.

People have now started to raise voice to oil companies about waste water and fracking. Even the rules have changed, in terms of effects on this slurry on environment. Thus pipe jacking machines separation units is must to have with oil and construction companies, other options like Mixing and Grouting Plants, mine tailings treatment stations also needed.

It requires huge efforts in this area and very much needed to happen and fast.In some instances, Water Recycling has become relatively so easy that with just takes a filtration system to take out solids from the wastewater. One model is in the automotive industry, to clean the model shells, a paint-shop wash-water isused and the vast majority of this waste water was of relatively consumable quality. With minimal filtration treatment can be reused.

Like Scandinavia, great technology leaps are needed to make to recycle waste water and convert them resource to create energy. We need to lesson from Sweden who ran out of waste and is now in need to import waste to create energy. They dump less than 1 % of waste and their water filtration techniques is so advanced that water can also be potable. This has set a great example or a model for us to step to innovation in an environmental capacity. And Sweden isn’t in different era than rest of other.

The recycling (by Pipe jacking machines separation plants) of the slurry has now become a great option in a way to eradicate scarcity of water. We are on down slide of the slope in water conservation with great developments and increasing populations. Considering these facts, with some open mindedness, innovative thinking and waste water treatment methods we can contribute to make some needed changes in the world.