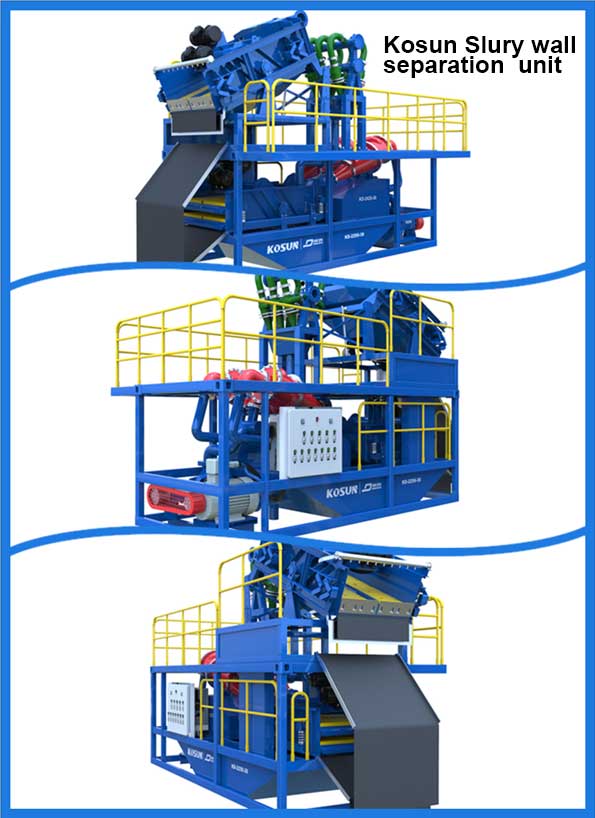

KOSUN KD-500 slurry treatment plant (Water and Sludge Separator) for mud balance shield is of modular structure design, which is specialized for mud purification in medium slurry balance shield construction projects.

KD-500 slurry treatment plant (Water and Sludge Separator) system consists of scalping shaker module and two sets of desanding modules. Equipped with coarse-mesh screens, the scalping shaker module is used to remove large particles, and the desanding module is equipped with a desander and a primary shaker.

The mud falls into the collecting box via scalping shaker, and then is divided into two sets of desanding modules through two connecting pipes. Each desanding module is equipped with a desander for sand removal from the mud. After two staged treatment, the recycling effect can be achieved.

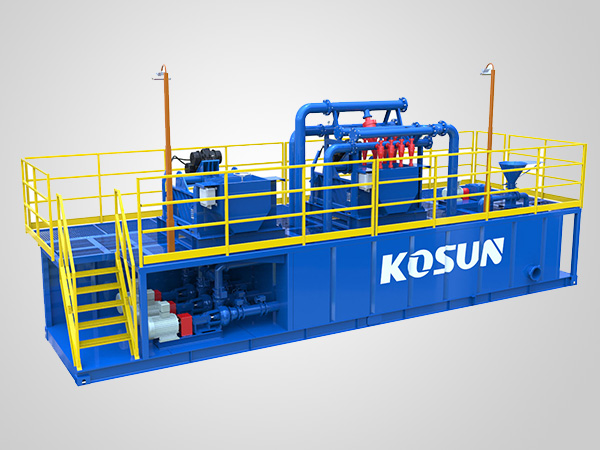

Main Technical Parameters of KD-500 Slurry Treatment Plant for Mud Balance Shield:

-Max. Capacity: 500m³/h

-Max. Mud Density: 1.18g/cm³

-Sand Content (measured by elutriation meter):<18%

-Main Body Volume: 4.6m³

-External Dimensions: 7600×4050×3900mm

-Total Power: 212kW

Wide Application Of KOSUN slurry treatment plant (Water and Sludge Separator):

1.Engineering Mud Treatment

2.Dredging sludge treatment of rivers and lakes

3.Urban pipe network sludge treatment

4.Sludge treatment of sewage treatment works

5.Remediation and control of contaminated soil

6.Tailing treatment and utilization

KOSUN is committed to providing customers with one-stop environmental treatment technologies and services in the above six fields, thus really realizing energy conservation and emission reduction. (Editor:Kosun Lily.Wang)

Kosun- China Solids Control Leader&Drilling Waste Management Expert

Tel.: +86 29 87304914

Email: sales2@adkosun.com

Contact person: Lily Wang

Online consulting: