Drilling fluids in HDD solids control system solution: First of all we need to know what the setup is going to be. Which kind of pump volume, bit setup, jet bit or mud motor, rig size, drill pipe size and brand, tool joints size, and many more. Many people will give you advice, but most of the problems who are happening are hardware related. Fluid is pretty simple, but the problem is that many people have no idea about the hardware setup. The easiest way is to send us the bore profile, and further above information and we can give you an advice based on the hardware.

Good low end rheology 6 rpm reading needs to be 1 to 1.5 times the bit size, excellent bridging capabilities, no damaging, wall cake that is easily removed, Very low fluid loss, a minimal amount of solids and those solids preferentially CaCO3, the remainder of the density requirement can be the same brine as the completion.You can use sized barite and shaker screen it out when it comes back, but you will end up with some barite in your DIF fluid.

In HDD solids control system solution we don’t need to remove the wall cake, only in vertical water wells we need to remove the filter cake to get the well flowing. We do this with the use of water in combination with a thinner, who is breaking down the bentonite filter cake. With some extra energy with a swab tool the filter cake is being removed mechanical, when the swab tool comes down the thinner is forced into the bentonite platelets and the charge of the bentonite molecules is dissolving.

We are not drilling water wells. What we drill is oil well deeper more than 10,000 ft and even deeper. Why we drill this. We drill this for oil. Oil comes from reservoir. So care must be taken to Drill this 5 to 10 mtr interval. We drill the reservoir zone with solid free RDIF and in this Fluid we don’t add even pinch of bentonite. After drilling this interval is cleaned by various treatment to prove the true non damaging system. Reservoir gives us the Millions of oil and gas we should not drill with cheap fluid. We use best of best fluid most of time polymers and best of best technology for solids control system.

After passing 60 degrees you will absolutely get a cuttings bed in the bottom portion of the build the most effective way to remove this bed is to reciprocate the pipe while pumping a tandem sweep consisting of a thin light weight pill followed by a high density pill I do not recommend going over 2ppg the mud weight. Besides, all of our Brightway products making out of 316L stainless steel sheet for motor. I do recommend making the pills such a volume that the combined volume is the same density as the active volume thus not shocking the lateral stresses already in place on the well bore from the active mud. Agreed higher low end rheology is required here as I stated earlier in this thread.

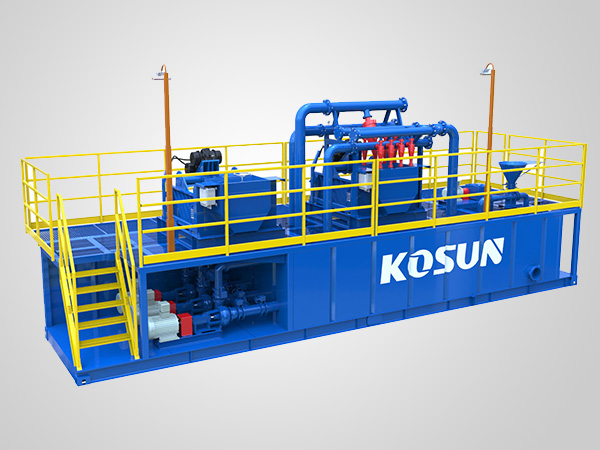

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

WhatsApp/Wechat:+86 18792396268

Contact person: Lily Wang

Online consulting:

http://www.kosun.com

http://www.kosuneco.com