Xi’an Kosun Machinery Co., Ltd. is the benchmark in the solids control industry, specializing in the design and production of cutting-edge solids control equipment and systems. With a focus on innovation and efficiency, the company has established itself as a leader in providing high-quality solutions for the management of drilling fluids in various industries.

One of the flagship products offered by Xi’an Kosun is their state-of-the-art mud solids control system. This system is designed to effectively manage the drilling fluids used in oil and gas exploration, mining, and other drilling operations. By utilizing advanced technology and engineering expertise, the mud solids control system ensures the removal of harmful solids and contaminants from the drilling mud, allowing for the efficient and sustainable extraction of resources.

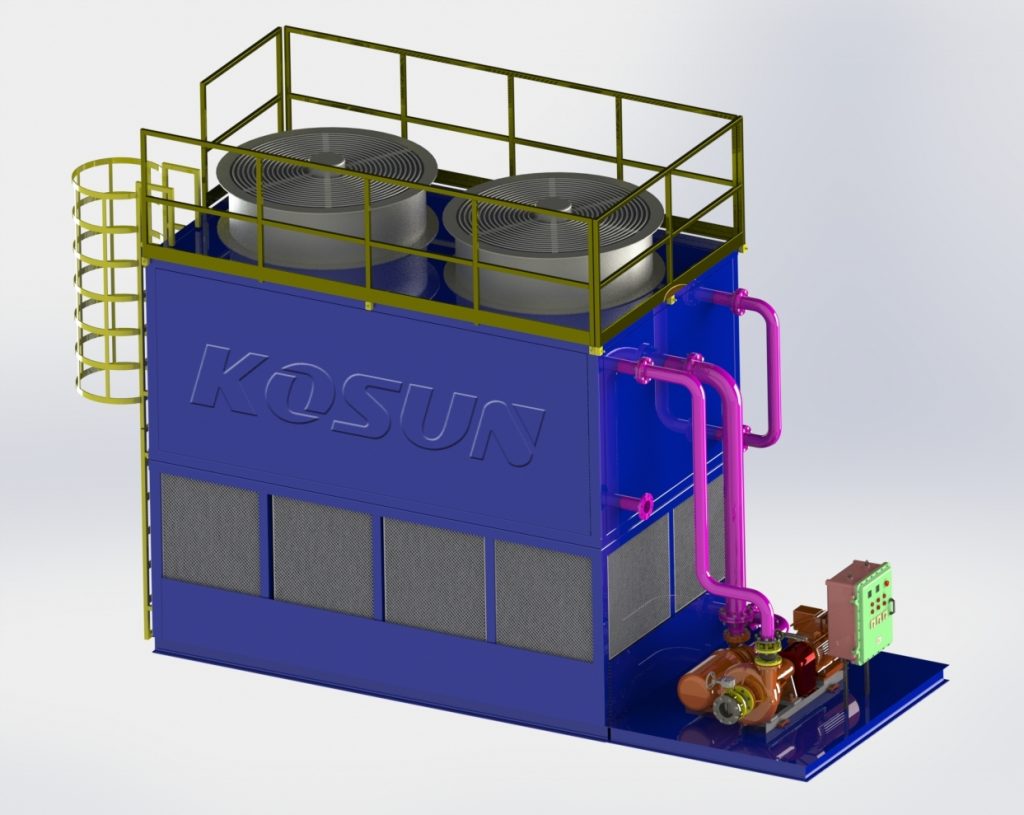

The mud solids control system offered by Xi’an Kosun is a comprehensive solution that includes a range of equipment such as shale shakers, desanders, desilters, and centrifuges. These components work together to separate the solids from the drilling fluid, ensuring that the mud can be reused and recycled, reducing waste and environmental impact.

In addition to the mud solids control system, Xi’an Kosun also provides mud tank systems and mud purification systems, further enhancing the efficiency and sustainability of drilling operations. These systems are designed to optimize the storage and treatment of drilling fluids, ensuring that the mud remains in optimal condition for use in the drilling process.

With a commitment to continuous improvement and customer satisfaction, Xi’an Kosun Machinery Co., Ltd. is dedicated to providing innovative solutions for the solids control industry. Their mud solids control systems and related equipment are designed to meet the evolving needs of the drilling sector, offering reliable performance and cost-effective operation.

In conclusion, Xi’an Kosun Machinery Manufacturing Co., Ltd. stands out as a leading provider of solids control equipment and systems, with a focus on delivering cutting-edge solutions for the management of drilling fluids. Their mud solids control systems, in particular, showcase their commitment to innovation, efficiency, and environmental responsibility in the industry.