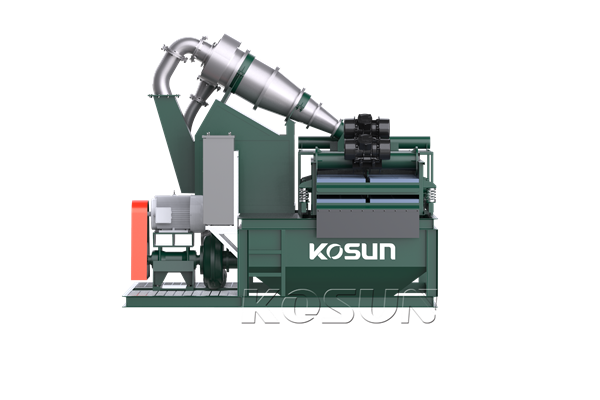

Oil-based drilling cuttings processing equipment refers to the machinery and systems used in the oil and gas industry to process and treat the drilling cuttings generated during the drilling of oil-based muds. These equipment are designed to separate the drill cuttings from the drilling fluid, recover valuable drilling fluid for reuse, and reduce the environmental impact of drilling waste. Here are some common types of oil-based drilling cuttings processing equipment:

1, Vertical Cuttings Dryer (VCD):

A vertical cuttings dryer is a key component in the cuttings processing system. It uses centrifugal force to remove drilling fluids from the cuttings. The cuttings are fed into the dryer, where they are rotated at high speeds to remove the liquid phase. The recovered drilling fluid is discharged for reuse, while the dried cuttings are further treated or disposed of.

2, Screw Conveyors:

Screw conveyors are used to transport the cuttings from one process unit to another. They are designed to handle the cuttings efficiently and continuously. Screw conveyors can be used to transfer the cuttings from the vertical cuttings dryer to the next stage of processing or for final disposal.

3, Decanter Centrifuge:

A decanter centrifuge is another essential piece of equipment used in oil-based drilling cuttings processing. It uses high-speed rotation to separate the finer solids and residual drilling fluids from the cuttings. The centrifuge works based on the principle of differential settling, where the heavier solids are forced to the outside while the lighter fluids move toward the center for recovery.

4, Thermal Desorption Unit (TDU):

In cases where the drilling cuttings contain high levels of hydrocarbons, a thermal desorption unit is employed. The TDU utilizes heat to vaporize and separate the hydrocarbons from the cuttings. The recovered hydrocarbons can be recycled or sold, while the treated cuttings are typically disposed of or used for alternative applications.

5, Shale Shakers:

Shale shakers are primary solids control equipment used to remove larger cuttings and solids from the drilling fluid. They consist of vibrating screens that allow the fluid to pass through while separating the cuttings. The separated cuttings are collected and further processed using other equipment.

6, Mud Tanks and Agitators:

Mud tanks are large containers used to store and process the drilling fluid. Agitators are installed within the tanks to keep the fluid properly mixed and prevent solids settling. The mud tanks provide a central location for the drilling fluid to be circulated and treated, while also allowing for the settlement and collection of cuttings.

7, Drying Shaker:

A drying shaker is similar to a shale shaker but with additional drying capabilities. It is used further to remove liquids from the cuttings after the initial treatment. The cuttings are passed over a vibrating screen, and the remaining drilling fluid is collected for further processing or recycling.

8, Cuttings Storage and Transport Systems:

Once the drilling cuttings are processed and treated, they need to be properly stored and transported for final disposal. This may involve specialized containers or skips that are designed to safely contain and transport the cuttings to approved waste management facilities.

It’s important to note that the specific combination and configuration of equipment can vary depending on the drilling operation, regulations, and environmental considerations. The selection and utilization of oil-based drilling cuttings processing equipment should comply with industry standards and local regulations to ensure effective treatment and minimize environmental impact. KOSUN is a 30+ years manufacturer of Oil-based Drilling Cuttings Processing Equipment, if you have related needs, please contact us for enquiry.

Tags: Oil-based Drilling Cuttings Processing Equipment, treat the drilling cuttings, separate the drill cuttings from the drilling fluid, suppliers, manufacturers, factory, wholesale, buy, price, quotation, bulk, for sale, companies, stock, cost.

Related Products:

https://www.kosun.com/products/drilling-waste-management/