Shield construction technology is one of the non-excavation methods. It is a fully mechanized construction method in the subsurface excavation method. It pushes the shield machine into the ground and supports the surrounding rocks through the shield shell and segments. To prevent collapse into the tunnel, at the same time use a cutting device to excavate the soil in front of the excavation, transport it out of the tunnel by an excavating machine, press the jack at the rear to push it in, and assemble precast concrete segments to form a tunnel A mechanized construction method for structures. The slurry circulation between the shield machine and the Slurry Treatment Plant is realized by the slurry conveying system. The soil and sand excavated by the shield machine enters the cutting silo, and the agitated high-density mud water is pumped by the mud pump to the shield Slurry Treatment Plant. The system, after the mud processing system is processed, is pumped back to the excavation surface, so that the mud is recycled in the equipment.

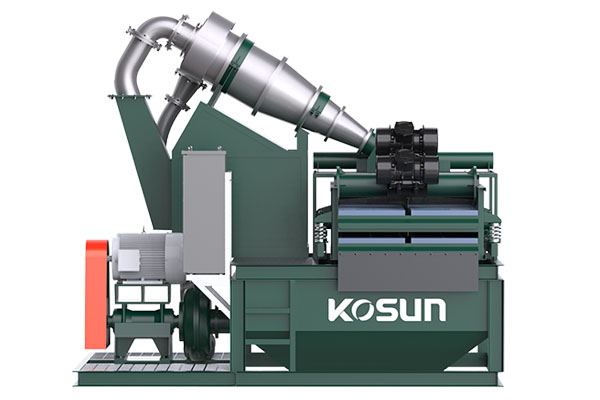

Design highlights of KOSUN shield mud-water separation equipment

1. High degree of automation: the feeding, separating, unloading and other processes at work are continuously and automatically carried out under high-speed operation, and the automatic control of centrifugation and separation is realized by programmable control.

2. Working performance: The differential used in the mud dewatering machine is a two-stage involute planetary gear differential and a cycloid pin wheel differential that rotates. The working temperature is low, the transmission torque is large, and the performance is reliable. The design of the anti-blocking device of the screw pusher can make the power larger, which has a great effect on the torque of the equipment itself, so that the work performance is better.

3. Strong craftsmanship: The belt filter press adopts double motors and double frequency conversion energy feedback differential speed for flexible stepless adjustment and online intelligent control, and can adjust the speed and differential speed at any time according to the changes of materials. In order to achieve the energy-saving effect.

4. Low noise: The cover adopts a double-layer design with sound insulation layer, and the cover and bearing seat adopt a new type of sealing structure, coupled with precise dynamic balance, so that the noise is significantly reduced.

5. Large processing capacity: The new centrifuge has a large processing capacity due to structural improvements such as the deepening of the liquid pool, the direct rotating drum, and the clear phase guide hole on the spiral.

6. Reliable performance: The sludge dewatering machine is equipped with torque protection, power control and other protections, which can effectively eliminate or damage the machine caused by sudden failures. All transmissions are equipped with protective covers.

7. Good working site: The separation of materials by Slurry Treatment Plant is carried out under closed conditions to ensure that the operation site is clean and pollution-free, and the production is clean and hygienic to achieve clean production.

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

Wechat:+86 18792396268

Contact person: Lily Wang

Online consulting:http://www.kosun.com