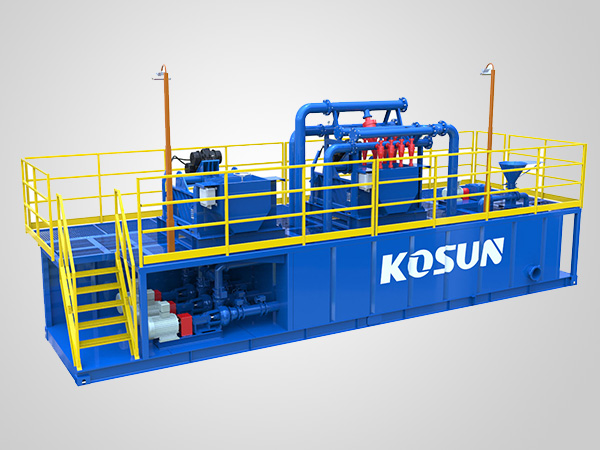

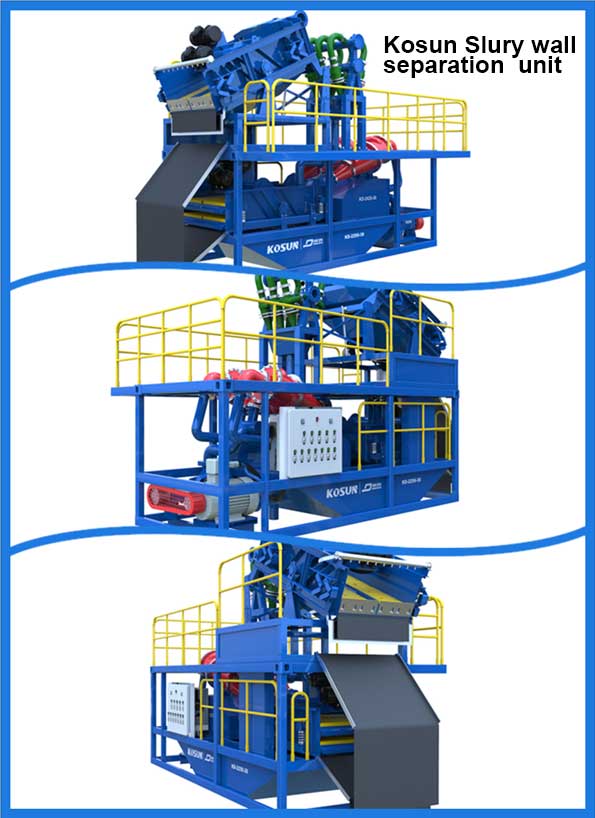

Slurry wall separation unit

Slurry wall separation unit (or diaphragm wall separation unit) are being used in underground wall construction (off course, the Slurry wall separation unit (or diaphragm wall separation unit) being placed above the ground), and the main function is to recycling the slurry (mud) and removing the solids from the slurry as well using in work.

diaphragm wall separation unit

Many product in slurry wall separation unit can burns on skin due to their low temperatures. Exposed body part can be torn as it has ability to stick to cold stuffs due to availability of moisture. These liquids can also cause

– Hypothermia or Frostbite

– Serious respiratory problems like pneumonia if cold gas is inhaled

– Reduced vision

Hazards from oxygen in diaphragm wall separation unit of Slurry Separation plants.

Oxygen is not a combustible gas but it helps flames to keep on going. Also hydrocarbon materials of lubrication oils react vigorously with oxygen and it should be avoided in all cases. Oxygen concentration should be kept below 23.5%.

Slurry Separation plants

Gas products occur need slurry separation plants.

Oxygen is most required for life support. When enough quantity of argon and nitrogen is present in environment it can lead to depletion of oxygen. Increase in hydrocarbon can also lead to symptoms like nausea or dizziness. In such cases one should come or brought out immediately. With time body returns to normal state once out of these conditions.

Protected clothing helps in protection of body from fire hazards or oxygen or cryogenic liquids.

– Leathers gloves should be used as their fitting is loose and can be easily removed in case of burns.

– Face shield to cover the face should be used.

– Footwear should be devoid of metals or nails as they can cause sparkling.

– In cases of trapped vapors, clothing should be opened and closed immediately

In slurry separation plants, like Kosun from China, the different parameters been collected in real spots and researched in labs, and finally give the corresponding solutions for remove the solids in constructions, like slurry wall separation or diaphragm wall separation.