Kosun Environmental Engineering oil sludge treatment scheme 1:Air flotation scheme for oil sludge recovery and separation system.

The application of the air flotation scheme in the oil sludge recovery and separation system can effectively realize the separation of oil, water and mud, and recover the reusable oil products in the sludge. At the same time, targeted chemical agents are used to reduce the oil content of the discharged sludge, with the lowest oil content of 0.5%, meeting the environmental protection emission standard.

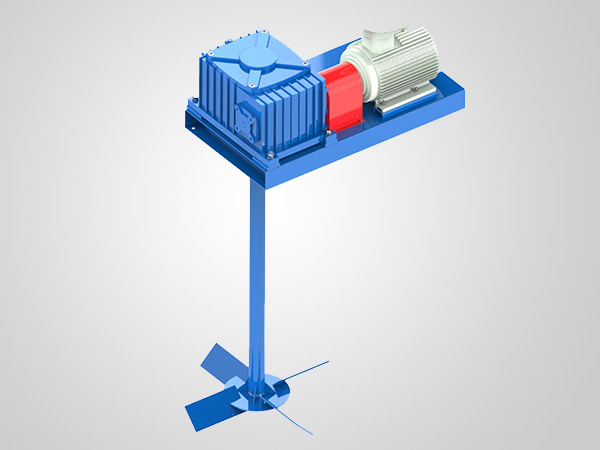

Kosun Environmental Engineering oil sludge treatment scheme 2:Skid-mounted oil sludge treatment system.

On the basis of introducing advanced separation technology from Europe and combining with domestic military manufacturing team, Kosun Environmental Engineering is specialized in manufacturing high-speed horizontal screw centrifuges.With the development concept of combining independent research and introduction, the company strives to make a breakthrough in the application function of centrifuge physics, so as to solve the secondary pollution problem caused by chemical treatment.Company research and development of special oil sludge, dirty oil, aging oil two phase and three phase horizontal screw centrifuge won the unprecedented good results in production practice. The various indicators are better than national standards, with a core of the special oil sludge horizontal screw centrifuge treatment system is fully operational, it will reduce the labor intensity of users, reduce the production cost of the using enterprise, at the same time can also provide cost-effective manufacturing in China for the international market.

Kosun Environmental Engineering oil sludge treatment scheme 3:Analytical processing technology of electric radiation and heat.

Kosun Environmental Engineering analytical processing technology of electric radiation and heat is mainly composed of “sludge pretreatment + analytical processing of electric radiation and heat + water treatment” and other processes.In order to meet the requirements of “reduction” of the factory, this scheme mainly realizes reduction of oily sludge through the analytical processing technology of electric radition and heat, which make the liquid phase reduction rate over 94%.

Application range of Kosun Environmental Engineering oil siudge treatment:

1.Drilling mud

2.Field oil

3.Oil field drilling oil base mud deoiling treatment

4.Waste machinery lubricating oil and emuision oil treatment

5.Fracturing fluid and flowback effluent

6.Complex mixed oil sludge from industrial oil sludge garbage pit

7.Pelagic tanker bilge oil sludge

8.Oil refinery water treatment oily scum and oily bottom sludge and so on

9.Oil sludge at tank bottom of oil field union station

10.Sediment isolation layer in natural sedimentation and dehydration of oil field union station

11.Slag containing sludge from ship fuel oil and lubricating oil separator

12.Coal tar is extracted from coal chemical industry

13.Aging oil of oil field union station

14.Oil-bearing scum produced during water treatment in oil field

15.Oily sludge treatment in oil chemical plants

16.Other Mineral-bearing oil sludge sand treatment

Tel.: +86 29 87304914

Email: sales2@adkosun.com

Contact person: Lily Wang

Online consulting:

http://www.kosun.com

http://www.kosuneco.com