KOSUN is a top manufacturer of Horizontal Directional Drilling(HDD) Mud Equipment/HDD Mud Recycling System

Are you gearing up for a Horizontal Directional Drilling (HDD) project and in need of top-notch Mud Equipment to ensure smooth operations? Look no further than KOSUN Solids Control – the leading manufacturer of HDD Mud Recycling Systems. Let’s dive into the world of efficient mud purification equipment and discover why KOSUN should be your go-to choice for your next HDD venture!

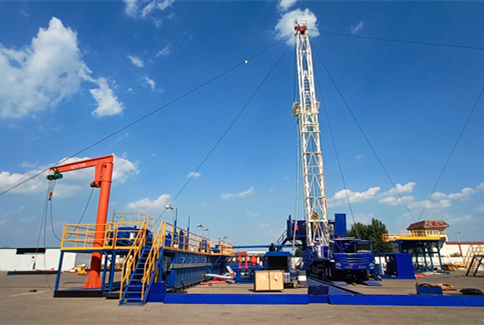

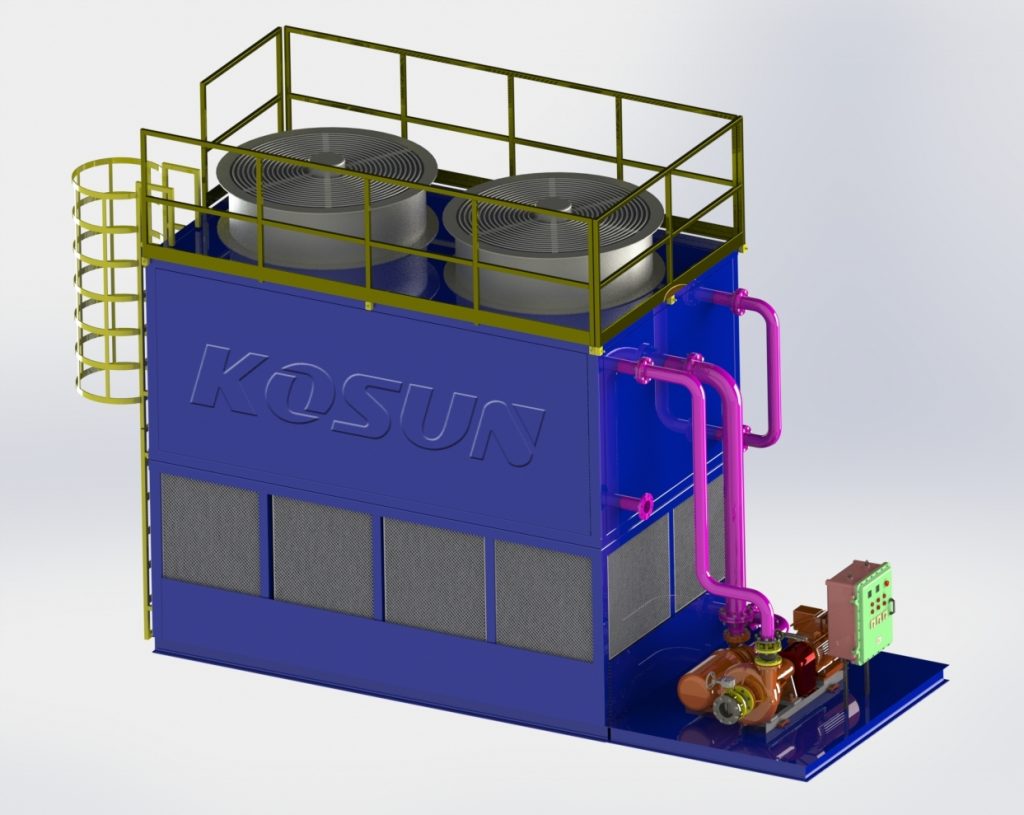

KOSUN Solids Control stands out as a premier manufacturer of Horizontal Directional Drilling (HDD) Mud Equipment and Recycling Systems, with a proven track record in countries like Australia, Indonesia, and India. Their comprehensive line of Mud Systems includes the KSMR series ranging from 100 to 1000 GPM, offering self-contained solutions for efficient mud recycling.

One key advantage of KOSUN’s offerings is their cost-effective equipment integration, providing complete drilling mud solutions from a single source. This streamlined approach not only saves time but also optimizes project efficiency.

Moreover, KOSUN’s fast-moving compact systems are designed for convenience, featuring a small footprint design with quick connections for removable parts. This ensures easy transportation while meeting all relevant regulations.

Additionally, KOSUN prioritizes customer service by offering experienced engineers for installation and training purposes. This commitment to support sets them apart in delivering end-to-end solutions tailored to each client’s needs.

To accommodate varying project requirements, KOSUN offers flexible options for Mud Tanks such as Skid Mounted, Trailer Mounted or Hydraulic Jack Up configurations. These choices empower clients to select the most suitable setup based on their specific operational demands.

The Importance of Mud Equipment in HDD Projects

In HDD projects, mud equipment plays a crucial role in ensuring smooth drilling operations. The mud recycling system is essential for maintaining the stability of the borehole and carrying cuttings back to the surface. Without efficient mud equipment, the drilling process can be compromised, leading to delays and increased costs.

Properly treated drilling mud helps to cool down and lubricate the drill bit, preventing overheating and wear. It also assists in controlling formation pressure and minimizing environmental impact by containing contaminants within the system. As a result, using high-quality mud equipment enhances operational efficiency and overall project success.

With KOSUN’s top-notch HDD Mud Recycling System, contractors can benefit from advanced technology designed to optimize performance while meeting stringent industry standards. Investing in reliable mud purification equipment is key to achieving superior results in HDD projects across various terrains and conditions.

KOSUN’s Top-Quality HDD Mud Recycling System

When it comes to top-quality HDD mud recycling systems, KOSUN is the name that stands out in the industry. With years of experience and a commitment to innovation, KOSUN has developed a range of cutting-edge equipment designed specifically for Horizontal Directional Drilling projects.

KOSUN’s HDD mud recycling system is known for its efficiency and reliability in maintaining drilling fluid properties while minimizing waste. The system effectively separates solids from liquids, allowing for continuous operation without compromising on performance.

One key aspect that sets KOSUN apart is its cost-effective equipment integration – offering complete drilling mud solutions from a single source. This not only streamlines the procurement process but also ensures compatibility between different components of the system.

For HDD projects where space and mobility are crucial factors, KOSUN’s compact design with fast connection features proves to be a game-changer. Whether it’s skid-mounted, trailer-mounted, or hydraulic jack-up tanks, KOSUN offers flexible options to cater to diverse project requirements.

Tags: HDD Mud Recycling System, Horizontal Directional Drilling(HDD) Mud Equipment, HDD Mud Purification Equipment, HDD Trenchless Mud Recycling System, HDD Mud Purification System

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

WhatsApp/Wechat:+86 13379250593

Contact person: Monica Li

Online consulting:

http://www.kosun.com

http://www.kosuneco.com