In oil drilling operations, the cleanliness of drilling fluid directly affects drilling efficiency, wellbore stability, and equipment lifespan. As drilling depth and complexity continue to increase, traditional desanders and desilters alone are often insufficient to meet the requirements for efficient purification. The mud cleaner, which integrates both desanding and desilting functions into a single unit, has become an indispensable component in modern solids control systems. Leveraging its in-depth research in drilling fluid solids control technology, Xi’an Kosun has accumulated extensive experience in the design, manufacturing, and application of cleaners, providing reliable purification solutions for global oil and gas drilling projects.

The primary function of a mud cleaner is to further remove medium-to-fine particles that shale shakers are unable to separate, typically with particle sizes between 20 and 74 microns. If these fine solids are not removed promptly, they can increase drilling fluid viscosity, cause density fluctuations, and consequently raise drill torque, accelerate wear, or even lead to stuck pipes and wellbore collapse, creating serious safety risks. By combining centrifugal separation with screening, the cleaner efficiently removes solid particles without altering mud properties, maintaining smooth flow and stability in the drilling fluid circulation system.

During operation, pre-treated drilling fluid first enters the hydrocyclone separation unit of the cleaner. The high-speed rotation generates centrifugal force, which forces the heavier solids outward. The separated upper liquid layer then passes through a fine mesh screen for secondary filtration, ensuring that the discharged fluid is even cleaner. Xi’an Kosun’s drilling fluid cleaners feature an optimized fluid dynamics design, with low flow resistance, high separation efficiency, and stable overall operation. Even under high solid-loading conditions, the equipment maintains continuous, high-efficiency purification.

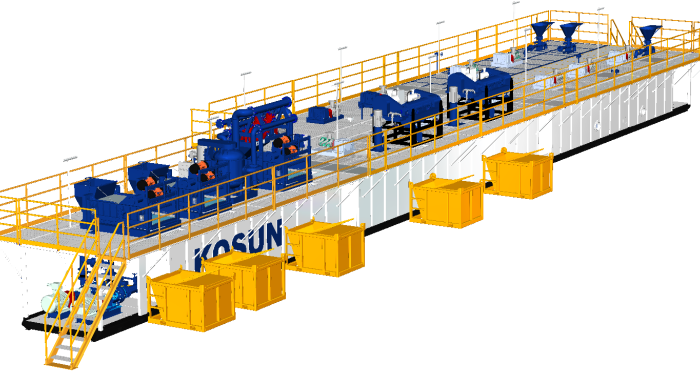

Compared with single-function devices, drilling fluid cleaners offer significant advantages, including a compact structure, strong processing capacity, and ease of maintenance. They can substantially reduce the load on downstream centrifuges, decrease the overall energy consumption of the mud treatment system, and extend the service life of drilling fluid, ultimately lowering drilling costs at the source. By incorporating a modular design concept, Xi’an Kosun ensures that cleaners can flexibly integrate with different solids control system layouts, whether for onshore drilling or offshore platforms, providing easy installation, commissioning, and maintenance.

In addition, Xi’an Kosun has carried out comprehensive optimizations in material selection and manufacturing processes. The main body of the equipment is made of wear- and corrosion-resistant steel, while the hydrocyclones are constructed from high-performance polymer polyurethane, offering excellent impact resistance and extended wear life. The screen section uses high-strength stainless steel composite screens, ensuring long-term screening accuracy and stability. Some models are also equipped with intelligent monitoring systems, which can real-time monitor pressure, flow, and vibration, providing operators with accurate data support and further enhancing system safety and automation.

The stable operation of drilling fluid cleaners not only improves mud circulation purification efficiency but also effectively protects the wellbore, reduces drill bit wear, and extends equipment lifespan, thereby increasing drilling efficiency while lowering costs. With over 30 years of industry experience, Xi’an Kosun adheres to the philosophy of “quality as the foundation, innovation as the guide”, continuously optimizing product performance and improving after-sales services to provide efficient, environmentally friendly, and cost-effective drilling fluid cleaning solutions for global oilfield clients.

Looking forward, Xi’an Kosun will continue to focus on innovation in solids control technologies, helping the oil drilling industry move toward safer, more efficient, and greener operations.