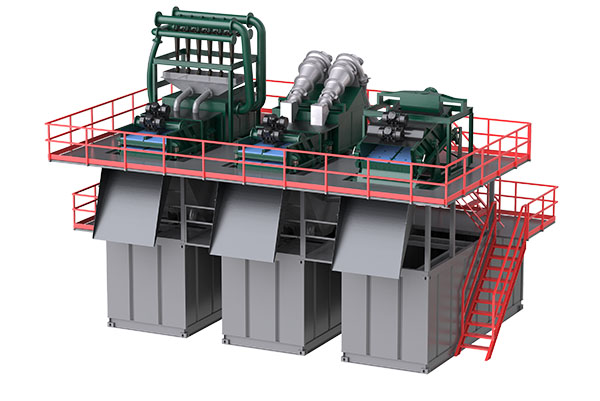

KOSUN MD series high efficiency mud cleaner is the second and third level solid control equipment of drilling fluid purification system, which can further separate the smaller particles solid phase contained in the mud treated by shale shaker, so that the mud can enter the fourth level separation equipment.

Features and advantages of KOSUN drilling mud cleaner:

1. Both desander and desilter hydrocyclones are made of polyurethane, high-chromium cast iron or ceramic and other wear-resistant materials;

2. The desander is equipped with 1-3 10° or 12° desander cyclones, which can separate particles of 45-74 microns;

3. The desilter is equipped with 8-20 4″ or 5″ desilter cyclones, which can separate particles of 15-44 microns;

4. During operation, the screen bed angle can be adjusted manually, with reliable performance, compact design and small space consumption;

5. Hook screen can be quickly replaced into a flat screen.

Precautions for mud cleaner operation:

1. Prior to the operation and maintenance of the cleaner, it is necessary to understand its structure and performance, as well as its installation in the well site through the manual;

2. Before using the cleaner, it is necessary to check whether the transport fixed bolt of the vibrating screen has been removed. During operation and maintenance, it is necessary to check whether the installation of the equipment is reliable and whether all parts have been connected in good condition;

3. Understand and be familiar with the working principle, working process, function of operation buttons, working pressure and screen cleaning of the cleaner;

4. Any parts shall not be adjusted or removed during use, and inspection and maintenance shall not be carried out during operation;

5. Make sure the power is off before the mud cleaner is maintained.

Kosun- China Solids Control Leader&Drilling Waste Management Expert

Tel.: +86 29 87304914

Email: sales2@adkosun.com

Contact person: Jinbo Zheng

Contact person: Jinbo Zheng