There are two types of subway shield machines: earth pressure balance shield machine and mud-water balance shield machine. Among them, the earth pressure balance shield machine does not need to separate the mud and water. Its essence is to excavate the soil, and the mud and water balance shield machine needs to separate the mud and water.

The principle of the mud-water balance shield machine is to stir the relatively moist soil at the front end of the shield into mud, and then pump out the mud to form a tunnel. The extracted mud needs to be separated from mud and water for environmental protection, and the water in it needs to be reused.

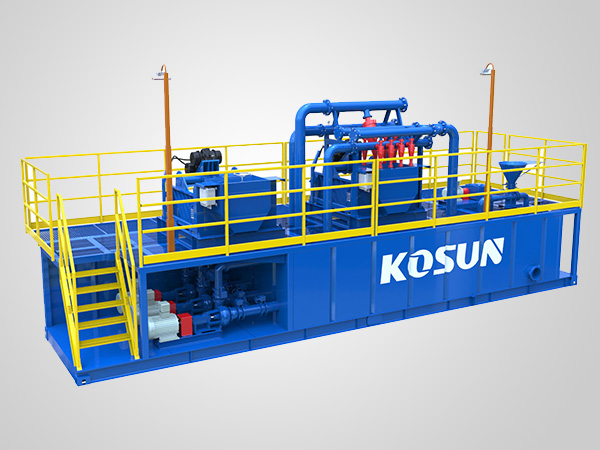

The mud-water separation needs to use a mud-water separator. The mud-water separator is divided into three layers, and sieves out the stone clods of different particle sizes, and then performs pressure filtration to realize the separation of soil and water. In this way, the pollution caused by the direct discharge of muddy water is avoided, and the reuse of water is also realized, and the separated soil can also meet the standard of safe discharge, so that the waste residue can be properly treated. Compared with the earth pressure shield machine, the structure of the mud-water balance shield machine is more complicated, and the mud-water separator also occupies a large area, so it is relatively less used, but in the wetter strata, such as Shanghai and other coastal areas, generally only can use the mud water Balance shield machine.

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

WhatsApp/Wechat:+86 18792396268

Contact person: Lily Wang

Online consulting:

http://www.kosun.com

http://www.kosuneco.com