In industrial fields such as oil drilling, shale gas development and mine exploration, the performance of drilling fluid (also known as mud) directly affects drilling efficiency, downhole safety and operation costs. The solids control system is precisely the core support system that ensures the continuous and stable operation of drilling fluid. As a professional enterprise deeply engaged in solid control equipment and system solutions, Xi ‘an Kosun, with years of industry experience, not only has a profound understanding of the technical essence of solid control systems, but also can tailor efficient and reliable solid control solutions for customers in different scenarios, helping the industry achieve green and efficient drilling operations.

In simple terms, a solids control system is a comprehensive equipment system that removes solid impurities (such as cuttings, sand grains, colloidal particles, etc.) from drilling fluid through classification separation and purification treatment, while recovering useful components (such as weighting agents, chemical treatment agents). During the drilling process, the drill bit breaks the formation rock, generating a large amount of cuttings. These cuttings circulate back to the surface with the drilling fluid. If not removed in time, it will lead to an increase in the viscosity and abnormal density of the drilling fluid, not only increasing the drilling torque and energy consumption, but also may cause safety hazards such as well gushing and well leakage, and even damage the drilling equipment. The core function of the solids control system is to “purify” the drilling fluid returning to the surface through scientific technological processes and professional equipment, restoring its performance to a state that meets the drilling requirements, achieving recycling and reuse. This not only reduces the waste of drilling fluid and lowers operation costs but also avoids environmental pollution caused by discarded drilling fluid, which is in line with the modern industrial green development concept.

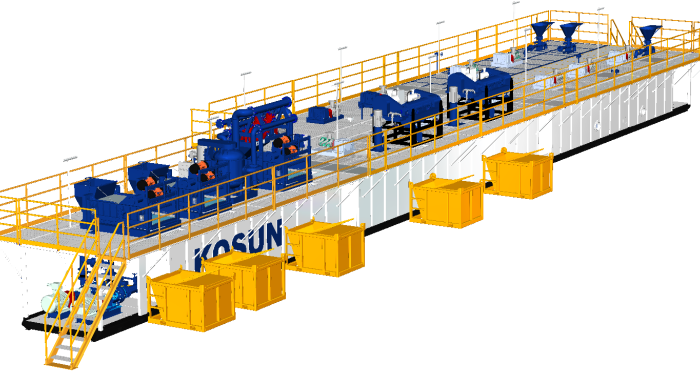

A complete fixed control system is not merely the simple superposition of a single device, but is composed of multiple core devices and auxiliary facilities with complementary functions working in coordination. This is also the focus of Xi ‘an Kosun in system design and integration. From the perspective of the process, the drilling fluid first enters the vibrating screen, which serves as the “first line of defense”. Through the high-frequency vibrating screen, large rock cuttings with a particle size greater than 75μm are filtered out, initially reducing the solid content. Subsequently, the drilling fluid containing medium and fine particles enters the desander, where the sand impurities ranging from 44 to 75μm are removed by cyclone separation technology. Then, the desilter comes into play, focusing on handling fine solid phases ranging from 15 to 44μm, further enhancing the cleanliness of the drilling fluid. For ultrafine particles with a particle size less than 15μm and colloidal substances, a horizontal screw centrifuge is used to deeply separate them through the centrifugal force generated by high-speed rotation, and at the same time, valuable weighting materials such as barite are recovered. All kinds of equipment work closely together to form a complete closed loop of “hierarchical purification – recycling”.

In scenarios such as sludge dewatering and industrial wastewater treatment in the environmental protection field, solid control systems also play a significant role. Xi ‘an Kosun can customize dedicated solid control solutions based on the composition characteristics of different types of wastewater and sludge. Through equipment such as horizontal screw centrifuges, it can achieve efficient solid-liquid separation, helping environmental protection enterprises improve treatment efficiency and meet discharge standards.

With the continuous improvement of the industry’s requirements for drilling efficiency, safety and environmental protection, the importance of solids control systems has become increasingly prominent. As a professional service provider in the solid control field, Xi ‘an Kosun has always closely followed the technological development trend and constantly innovated its products and solutions. From single equipment supply to complete system integration, from the initial scheme design to the later operation and maintenance services, Xi ‘an Kosun provides customers with “one-stop” solid control services, helping them achieve efficient, safe and green production in drilling operations.

From energy development to mining, and then to construction and environmental protection treatment, Xi ‘an Kosun’s solids control systems always take scene requirements as the core. Through technological innovation and customized services, they provide efficient and reliable solids control support for customers in various industries. In the future, Xi ‘an Kosun will continue to focus on the field of solids control technology, providing more advanced systems and better services to safeguard the high-quality development of industries such as oil drilling.