Desanding and desilting units

Desanding and desilting units, which is defined to make the component of the oilfield drilling solid control system(or the drilling waste management by Kosun), and the main mechanical parts of them are desanders and desilters. But in nowadays, these two parts are trenching its legs to other related industries, such as mud separation of AVN Machines, slurry treatment of Bored Piling Excavation, and the important parts of the mud separation system of diaphragm wall projection.

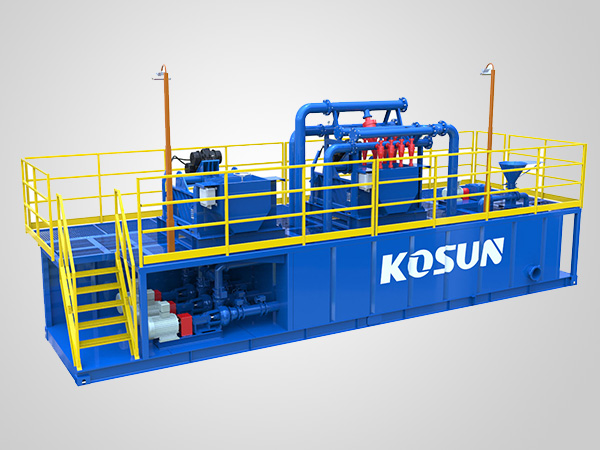

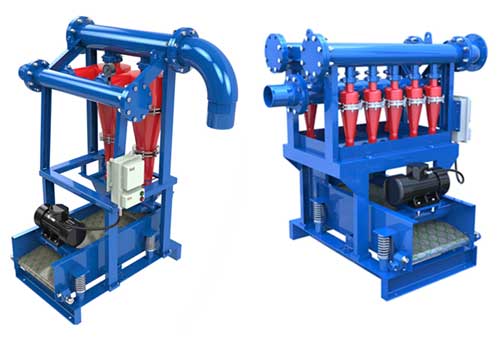

Here you can find good pictures of the desanding and desilting units like following:

According to the different situations of the projection target, the numbers of desander and desilters are different. But the basic procedures are roughly same, first step, the mud “walk” through the desander and make the “larger” particles in mud and fluids separate, and this can be finished by the usage of two or more hydrocyclones in the desanders; 2nd step, the first step “screened” fluids flow into the desilter, with more precise hydrocyclones (usually with 4 or 5 or more in numbers), and can separate 15-44um particles in mud, and the two system are running in a return mode, so the particles can be smaller and smaller, and finally got the desired and almost cleaned mud, that can be used again in projection.

There are many experienced desanding and desilting units manufacturers in the world, and they all have their unique advantages, for the most advanced technologies owned, maybe Germany companies will be your choices and for more convenience and cheaper price system with good quality one, maybe the 24 years China manufacturer – Kosun will be you good choice. Not only provide the new system of desanders and desilters, Separation unitsbut also can make the custom designed system and lone time technical representatives of every customer as their after sale needs.