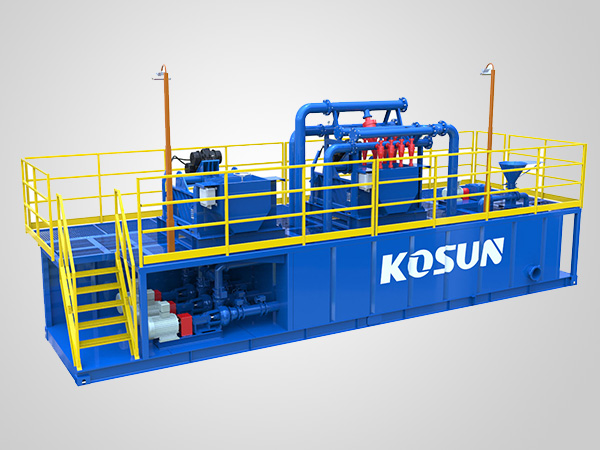

Tunnel Boring Machine Slurry System

Tunnel Boring Machine Slurry System of Kosun with more than 20 years experience.

Three main types of tunnel boring machine separators are used in soft ground excavations-

– Slurry shield TBMs

– Earth pressure balance machine

– Open – face type

In soft grounds with pressure less than 7bar, earth pressure balance machines are used. These along with cutting head also comprises tungsten carbide disc cutters, cutting bits and hard disk cutters.

Machine derives its name from the fact that it balances the pressure in tunnel head by use of excavated earth. Rate of excavation and advances through Archimedes screw controls pressure in the cutterhead. Some additives like bentonite may have to be injected to increase the stability.

These are also added to make sure that the earth is sufficiently attached to the Archimedes screw thus marinating the pressure in the head and prevent seepage of water in the tunnel.

Slurry shield TMBs are used in cases where the ground is so granular in nature that it cannot form plug in Archimedes screw. The cutting head is feeded with slurry which in turn applies pressure. This even acts as transporting medium as it mixes with excavated earth and is being pumped out in slurry separation units usually located out of tunnel. In this separation unit slurry is processed so that it is recycled and can be used again. This filtration is a multi- staged process. However, filtration of slurry depends on the size of excavated particles.

Thus making this slurry shield tunnel boring machine separation units suit able for clays and silts sized particles as they are smaller than bentonite particle, which makes the slurry. In these instances separation with water can be done which will help form clay cake thus filtering the slurry in the end.

In grounds where the excavated tunnels can stand without support for a little period, open face TMBs can be used. These tunnel boring machine separators are generally used where strength is more than 10Mpa and seepage of water is low. Cross sections of sizes up to 10 meters can excavated with these TMBs.

Cutter head excavates within 150mm of the shield edge. This shield is moved forwards and cut the ground in same circular manner. Pre-casted concretes or graphite iron segments provide ground support. The key spreads the rings until it is tightly fitted against the tunnel made by tunnel boring machine separators shields. Open face TMBs comes in many variations.