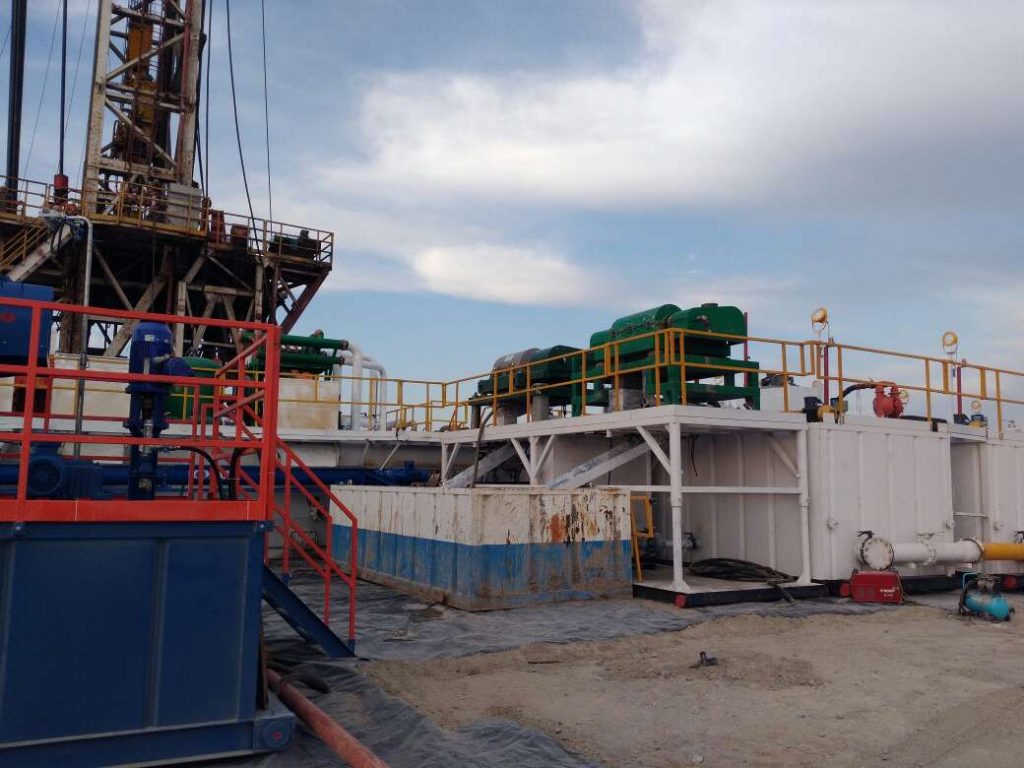

Operating principle of drilling mud non-landing system:

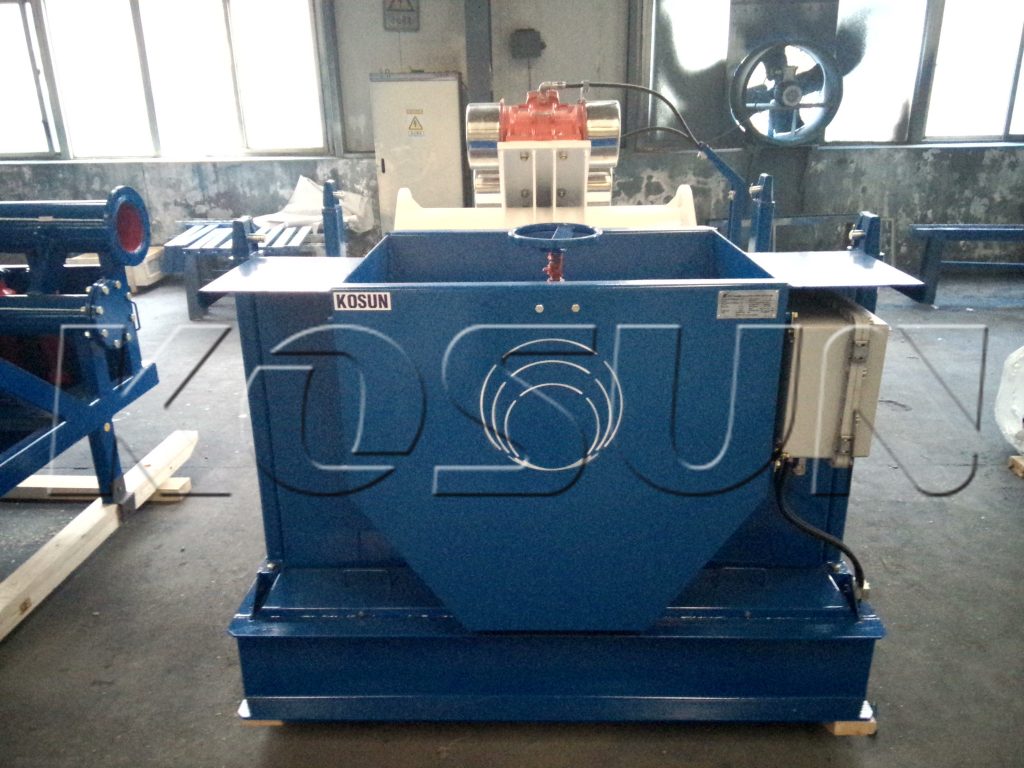

In the process of oil and gas field drilling, the drilling mud and cuttings are treated continuously while drilling through specific equipment and technology, and the treated mud is recycled repeatedly, and the cuttings and harmful substances are treated, so as to protect the soil at the drilling site from being polluted. The treatment process is divided into: first, solid-liquid separation and waste residue recovery unit; Second, the waste drying unit.

Advantages of drilling mud system:

The use of the non-landing mud system eliminates the direct excavation of the circulation pool, reduces land use, reduces related costs, and reduces the workload of the well team.Once the system is put into use, it can not only realize the continuous treatment of drilling mud and solid waste, but also recycle the two, which is both environmentally friendly and energy-saving.Mud pollution to the environment will be further controlled, drilling operations will be green.At the same time, the mud system can directly obtain good social and economic benefits.

1. The recycling and clean production of solid waste meet the requirements of circular economy and environmental protection, effectively reduce the environmental risk caused by waste drilling fluid, and help to protect the ecological environment;

Ii. The “smaller” mud and sewage pool reduces the occupied area of the land and saves a certain amount of land collection fee for the oil field company;

3. Compared with the curing treatment cost of waste mud mainly used before, the use of the non-landing mud system has the characteristics of low cost and good effect. Cuttings separated by this technology can be discharged to the standard. As paving material, crop cultivation soil, etc. The water can be recycled to achieve the purpose of waste utilization, energy conservation and emission reduction.