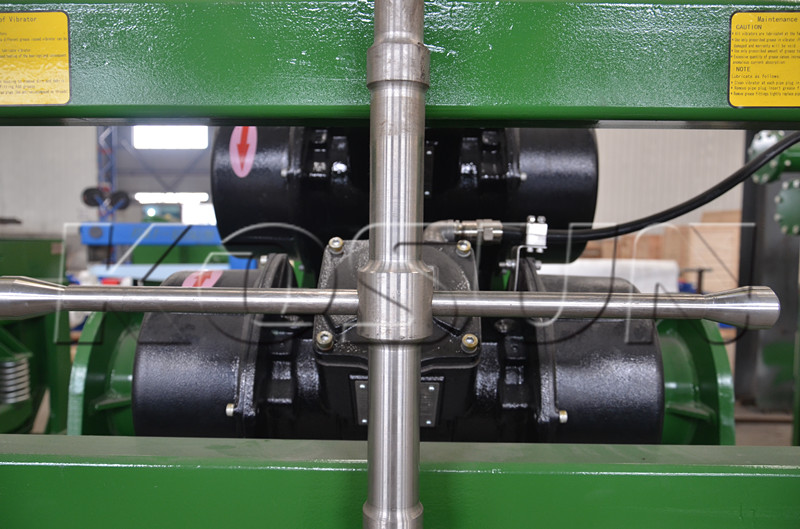

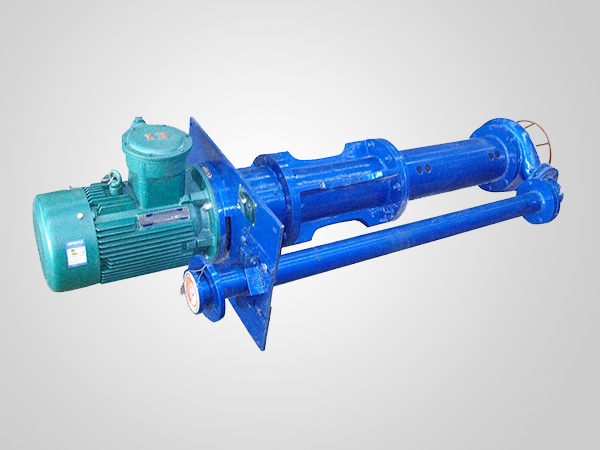

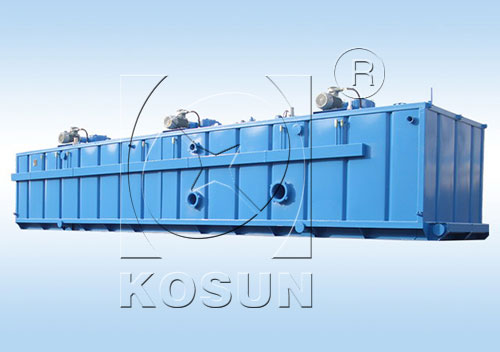

KOSUN DS series cyclone desiccator is an economical and suitable desander, which is the secondary desiccator in the process of the solid control system. Solid particles between 45 and 74 microns can be separated and the treated mud can be better treated by the equipment at the lower level.

Precautions for installation of hydrocyclone desander:

- The hydrocyclone desander shall be installed on the main pipe line of the water supply network and fixed on the base. Bypass shall be added between the water inlet and outlet pipes.

- In order to ensure smooth water flow, a straight pipe with equal diameter to the water inlet shall be installed before the water inlet of the equipment, whose length is 10-15 times of the diameter of the water inlet.

- Adequate maintenance space shall be reserved around the equipment during installation.

- Open the inlet and outlet valves, close the sewage valve and bypass valve during normal operation.

- According to the sediment content of the source water, discharge sand and remove pollution regularly. Open the sewage valve when discharging, and the sewage process will not affect the normal water use of the system.

- Close the blowdown valve after the blowdown is over.

- Close the valve at the outlet if sand discharge pressure is insufficient.

- This equipment has no function of filtering impurities. If there are requirements for filtering impurities, a filter should be installed.

Kosun- China Solids Control Leader&Drilling Waste Management Expert

Tel.: 029-89565356

Email: sales2@adkosun.com

Contact person: Jinbo Zheng

Contact person: Jinbo Zheng

http://www.kosuneco.com